Marketing

Manufacturing Cosmetics: How does it work?

Read on to find out more about how manufacturing cosmetic items work. Quality control is the final step in having your finished cosmetic product on the market and the shelves.

Cosmetic products are a hugely important resource in the lives of many in the modern-day, forming an essential part of routines that allow people to feel intelligent, presentable, beautiful, or stylish – or however they would like to fish since the range of products available on the market covers the comprehensive range of consumer needs.

Whether you’re shopping in a supermarket or a dedicated cosmetic item store, it’s easy to be blown aware by the sheer number of cosmetic products available. Each product is produced to solve a specific problem for a particular group of people. After all, everyone’s skin is different, and the way people want to present themselves depends on their unique characteristics.

It’s easy to look at cosmetic products such as moisturizers and take them for granted, as they are so easily accessible and readily available to consumers. However, taking raw ingredients and turning them into the highly polished products seen on the shelves is by no means a simple one and is the result of established manufacturing processes.

Read on to find out more about how manufacturing cosmetic items work.

1. Defining Purpose and Market Research

The first, crucially important step in producing a cosmetic item for the general market is defining your product’s purpose. As mentioned previously, the cosmetic market exists because people have issues they’d like to solve regarding their appearance or health, whether this is remedying dehydrated skin or creating a new makeup palette for an event or outfit.

Establishing product purpose allows for identifying particular substances or materials that will generate the desired results and for the product to be designed and marketed around these defining features.

Conducting market research on the available products will give you a great idea of what’s currently popular and the ingredients that consumers are now responding to.

2. Product Manufacturing and Creation

Once your product’s purpose, main ingredients, and desired market have been established, it’s time for manufacturing to begin. This is where the raw ingredients will be processed to produce your top-of-the-range eye shadow or general-purpose moisturizer.

In the case of makeup, such as lipstick, waxes and oils are mixed in varying quantities depending on the desired consistency. At the same time, the product’s active ingredients are also chemically integrated.

The raw ingredients often have differing qualities in areas such as viscosity, meaning that other third-party agents are required to integrate the product into one smooth entity.

3. Quality control

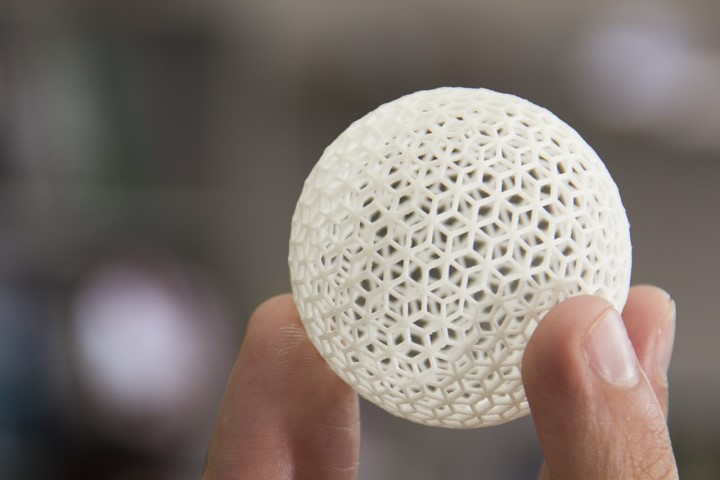

Quality control is the final step in having your finished cosmetic product on the market and the shelves. This is an essential step that utilizes powerful technology and processes, such as powder x-ray diffraction, to study the development at the molecular level to identify any impurities and the size and distribution of particulate.

Particle size and distribution play a critical role in the qualities of the final product, as they can affect the feel of the wearer in ways such as smoothness or coarseness, as well as viscosity, or liquidity.

-

Instagram4 years ago

Instagram4 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram4 years ago

Instagram4 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business5 years ago

Business5 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram4 years ago

Instagram4 years agoInstagram Followers And Likes – Online Social Media Platform