Health Sciences

How to Properly Store Hazardous Materials

Because your company uses hazardous materials in the manufacturing and production departments, these chemicals and other substances must be stored appropriately.

As a business owner, you are committed to the health and safety of your entire staff. Because your company uses hazardous materials in the manufacturing and production departments, these chemicals and other substances must be stored appropriately.

To ensure that your company is safely storing these materials, which will not only help ensure the safety of your team but also prevent these substances from being ruined and wasted, consider the following tips.

Table of Contents

1. Know What Gets Along and What Doesn’t

Even if you keep all chemicals in dry and cool, well-ventilated areas, you also have to consider the chance that a leak or spill could mean these substances will start intermingling. To avoid this dangerous and potentially fatal situation, learn the properties of the chemicals you have in storage and move those that don’t get along well with others.

For instance, acids should not be kept near alkalis because they will create heat if they mix. Similarly, hypochlorites should be stored far away from acids because they will combine to form chlorine gas if there is a leak.

2. Have the Correct Seals in Stock

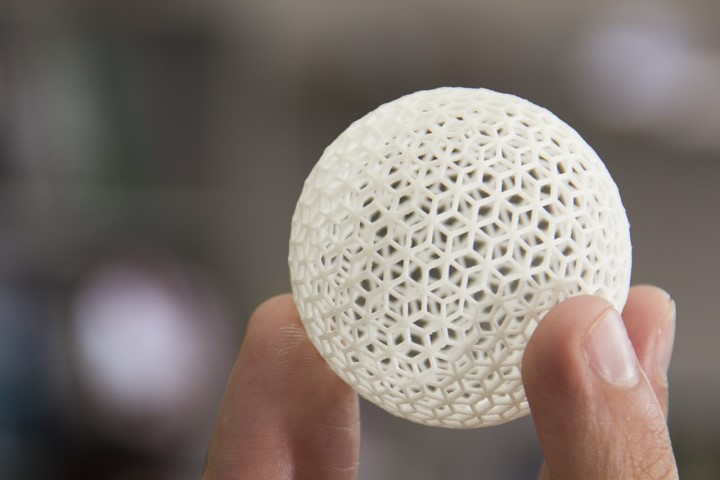

To help prevent these leaks from occurring in the first place, all storage systems must have the proper seals. As part of your hazardous storage procedures, these seals should be checked regularly and replaced as necessary. To do this in a modern fashion, you may want to keep several seals on hand.

Know that when it comes to o-rings and other seals in storage systems, they are not created equally; as Apple Rubber notes, fluorocarbon o-rings are the ideal choice in this situation, as they can stand up to a wide variety of chemical exposure situations.

3. Label Everything Extremely Clearly

No matter what kind of hazardous material you are storing or the vessels that contain them, one thing is true: everything must be clearly labeled. The last thing you want is for an unmarked can of a highly toxic chemical to end up being put away in the wrong area or accidentally opened and inhaled by a team member.

Create large and clear labels for each container and label your storage area to let others know they are entering a space that holds hazardous materials.

4. Learn About Shelf Life

Like many other manufacturing products, hazardous materials often have shelf lives. To ensure that you do not waste money by throwing away old chemicals, learn how different long substances last, and ensure stock is rotated appropriately. For example, if you keep gasoline on hand for equipment that runs on this type of fuel, Exxon notes that properly stored gas will maintain its quality for six months.

5. If It Can Catch on Fire, It Needs More Attention

Hazardous chemicals that are also flammable, like the gasoline mentioned above, require extra care when they are stored. For instance, the storage area must be well ventilated to make sure any escaping vapors can dissipate. Ensure the site itself is also fire resistant and that all flammable chemicals are kept in closed containers, and that they are far away from anything that might cause them to catch fire.

6. Safe Storage Is Paramount and Possible

You may have an incredibly safe company with an excellent track record of accident-free days. To maintain this unique safety culture, take the time you need to learn all you can about the hazardous materials you store every day. Then, as need be, separate the ones that don’t do well with others, keep seals and o-rings in stock, label everything, rotate stock, and be aware of what is flammable. These precautions and steps will help to keep your company and team as safe as possible.

-

Instagram4 years ago

Instagram4 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram4 years ago

Instagram4 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business5 years ago

Business5 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram4 years ago

Instagram4 years agoInstagram Followers And Likes – Online Social Media Platform