Marketing

Practical Tips on Choosing the Best Excavator Teeth

When you want to buy an excavator, you will always be looking out for the best machine on the market. Practical Tips on choosing the best excavator teeth.

When you want to buy an excavator, you will always be looking out for the best machine on the market. Here you can know some crucial factors to consider when choosing excavator’s teeth for a successful job.

If you want to get the very best out of your machines, it is important for you to get the right engagement tools. The engagement tools include the excavator bucket among others. In most cases when making a purchase of the excavator buckets, you will be limited to the tooth and the adapter system provided by the manufacturer.

This means that you have fewer chances of getting the best excavator bucket. You might end up getting the lowest quality of the excavator’s teeth if you are not careful.

Some of the manufacturers can use cheap excavator teeth in order to sell their buckets at a lower cost or increase their profits. It is therefore important to make sure that you choose an excavator with teeth that are working in an efficient manner.

The maintenance practices that you carry out on your excavator will determine the productivity since it reduces the stress on the machines. As the owner of the machine, you will be required to buy JCB genuine parts to replace the worn-out parts. By maintaining your machine, you are extending its life and lowering the costs incurred on the repairs.

The design and the fitting of the excavator will determine the life of the machine, its performance, and the different applications.

Since competition in the industry is based on the price, most of the manufacturers can compromise the quality of their products to get the price demands in the market.

These reductions in the quality of the products can lead to poor quality of the casting steel and short heat treatment process so that they do not become hard as expected.

The use of shortcuts in the manufacturing of the excavators will lead to poor teeth that can break easily and prematurely once they are exposed to any pressure.

So choosing the best teeth for your excavator buckets means you take your time and consider the important factors. These below aspects should guide you to make the best decision when you want to buy JCB genuine parts for your excavator machine.

Consider the following four factors:

Table of Contents

1. Factors to Consider When Choosing Excavator Teeth

a. Manufacturing

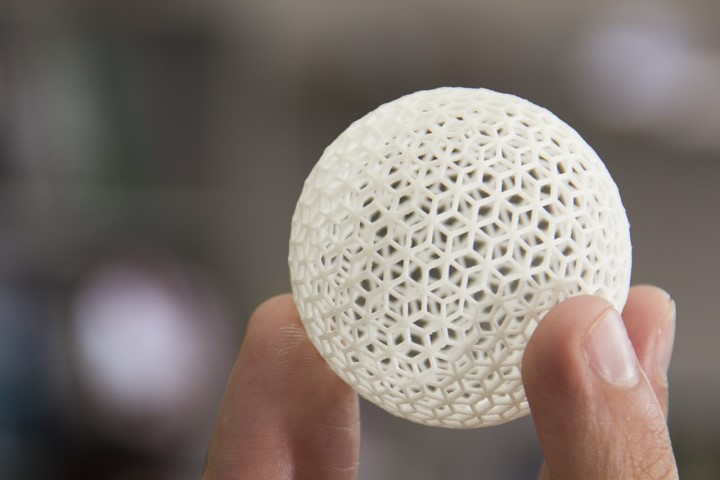

The material used in the construction of the excavator’s teeth and the way it has been constructed will determine the strength and the lifespan. The shape and design of the machine will also determine the lifespan of the machine.

Most of the teeth used on the machines are usually cast in third world countries due to pollution and cost factors. The particular type of materials used in the casting process and the molds which have been used in the construction will determine the exact time that the teeth will last before they break. The treatment process can also determine the hardness of the teeth.

b. Wear Life of the Machine

The wear life of the excavator will be affected by different factors. When the wear surface is great, the longer the time that the machine will last before a replacement.

The excavator’s teeth are designed to handle materials and load them on to the truck. They are not designed for use in excavation or building trenches since this will require a high penetration and impact.

c. Penetration

The surface area that will come into contact with the ground during the penetration process will determine the efficiency of the machine.

If the teeth are designed in such a way that it has a large blunt area or width, extra power will be required for the penetration of the material. More fuel will be used and stress will be created on the parts of the machine.

The teeth should be designed in such a way that it can self-sharpen itself as it wears out. If you want to penetrate a rocky or frozen place, you will be required to use ‘v’ shaped teeth. These teeth are more appropriate for the digging of trenches.

d. Impact

The teeth with high resistance on the impact of the machine can easily withstand the forces and the penetrating shocks. They are also best suited for the trenching applications when you are using the excavator backhoe or a machine with a higher force specifically on rocks.

The way in which the teeth have been fitted will also be important since failing to fit the teeth properly will exert pressure on the pin, thus creating a weak point on it. The pin can also easily drop out due to the pressure.

In the end, when you choose the right excavator teeth, you will increase your productivity and there will be fewer maintenance costs.

Helpful Resources:

1. 16 Best (free) AMP – (Accelerated Mobile Pages) WordPress Plugins

2. 16 Best Free SEO WordPress plugins for your Blogs & websites

3. Riverdale Cast List For The TV Show Riverdale

-

Instagram4 years ago

Instagram4 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram4 years ago

Instagram4 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business5 years ago

Business5 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram4 years ago

Instagram4 years agoInstagram Followers And Likes – Online Social Media Platform