Electronics

How Skilled are Product Engineers?

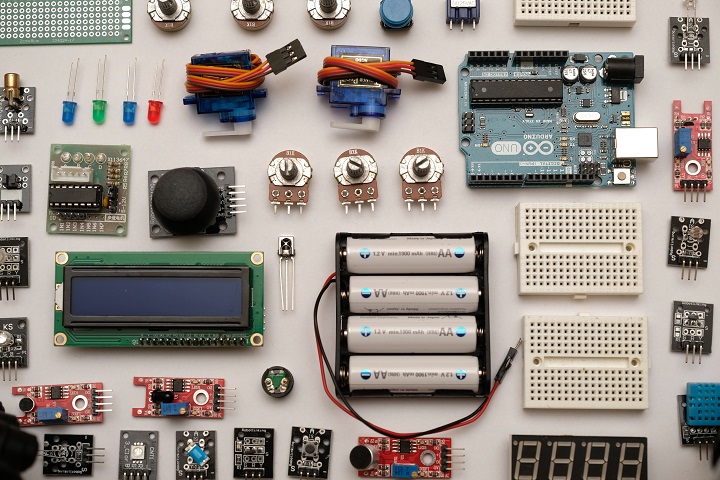

Real-world applications and success stories. Designing optimal parts for electronics with GD&T and testing knowledge.

Designing Optimal Parts for Electronics with GD&T and Testing Knowledge

In today’s fast-paced world of electronics manufacturing, the role of product engineers has never been more crucial. These professionals are responsible for designing and optimizing electronic components, ensuring precision, functionality, and reliability. To achieve these goals, product engineers need a diverse skill set that includes technical proficiency, problem-solving abilities, and knowledge of tools like Geometric Dimensioning and Tolerancing gd&t test procedures.

Table of Contents

1. Introduction

Defining the Role of Product Engineers

Product engineers play a pivotal role in the development of electronic devices. They are responsible for designing and optimizing the individual components that make up these devices, ensuring they function flawlessly in various applications.

The Significance of Designing Optimal Parts for Electronics

The quality of electronic components directly impacts the performance and reliability of electronic devices. Designing optimal parts is not just a matter of aesthetics but a fundamental aspect of ensuring the functionality of the final product.

Overview of GD&T and Testing Knowledge

Two critical elements in a product engineer’s toolkit are GD&T and testing knowledge. GD&T is a system for defining and communicating engineering tolerances while testing knowledge encompasses quality assurance procedures and protocols.

2. The Core Skills of a Product Engineer

To gauge the skills required by product engineers, let’s delve into their core competencies:

Technical Proficiency in Electronics

Product engineers must have a deep understanding of electronics, including circuitry, materials, and manufacturing processes. They need to be well-versed in the latest technological advancements.

Problem-solving and Critical Thinking

Every engineering project presents unique challenges. Product engineers must possess strong problem-solving and critical thinking skills to overcome these hurdles effectively.

Effective Communication and Collaboration

Working in a multidisciplinary environment is common for product engineers. Effective communication and collaboration with other professionals, such as designers and manufacturers, are essential for success.

3. Understanding GD&T (Geometric Dimensioning and Tolerancing)

What is GD&T and Its Importance in Engineering

GD&T is a symbolic language used to define and communicate the acceptable variations in form, size, orientation, and location of features on a part. It is crucial in engineering to ensure precise manufacturing and assembly.

Key Principles and Symbols of GD&T

GD&T employs symbols and principles such as position, concentricity, and profile to convey tolerances and requirements. Engineers use these symbols to specify how parts should be manufactured and assembled.

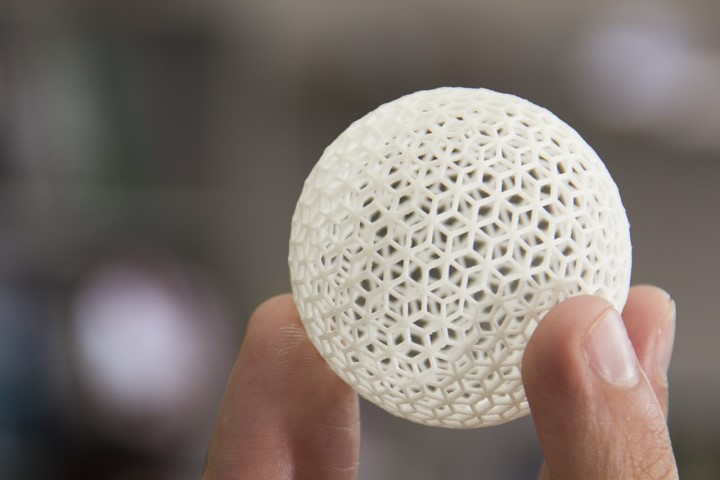

Practical Applications in Electronics Design

In electronics design, GD&T helps ensure that components fit together precisely, minimizing the risk of errors during manufacturing and assembly. This results in improved product quality and reduced production costs.

4. The Role of GD&T in Optimizing Electronic Components

Ensuring Precision and Consistency in Part Design

GD&T allows engineers to specify tight tolerances and ensure that electronic components are manufactured with precision and consistency. This leads to fewer defects and higher product reliability.

Reducing Manufacturing Costs and Errors

By clearly defining tolerances and requirements, GD&T helps manufacturers reduce errors and waste during production. This, in turn, leads to cost savings and increased efficiency.

Enhancing Product Performance and Reliability

Optimally designed electronic components, facilitated by GD&T, contribute to improved product performance and reliability. End-users can trust that their devices will function as intended.

5. Testing Knowledge: Quality Assurance in Electronics

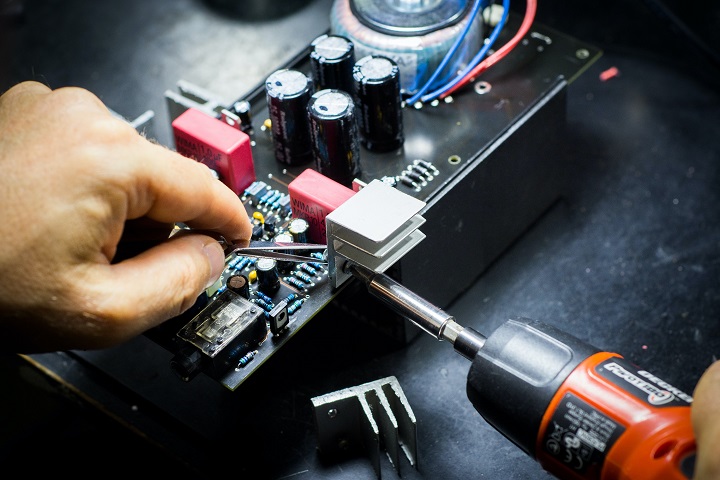

Importance of Quality Assurance in Electronics Manufacturing

Quality assurance is a critical aspect of electronics manufacturing. Testing knowledge ensures that products meet rigorous quality standards and perform reliably.

Types of Tests in Electronics Engineering

Product engineers must be familiar with various types of tests, including functional testing, environmental testing, and reliability testing. Each type serves a unique purpose in verifying product quality.

How Testing Knowledge Influences Design Decisions

Knowledge of testing procedures directly informs design decisions. Engineers must design components with testability in mind, allowing for thorough quality control throughout the manufacturing process.

6. The Intersection of GD&T and Testing Knowledge

How GD&T Affects Testing Procedures

GD&T plays a significant role in testing procedures, as it defines the allowable variations in components. Testing protocols must align with GD&T specifications to ensure accurate quality assessments.

Ensuring Compatibility and Accuracy in Testing

Product engineers must bridge the gap between design and testing. Components designed with GD&T in mind are more likely to be compatible with testing equipment, ensuring accurate and reliable results.

Case Studies on Successful Integration

Examining real-world case studies highlights the benefits of integrating GD&T and testing knowledge. These success stories demonstrate how these skills can lead to superior product quality.

7. Challenges Faced by Product Engineers

Despite their critical role, product engineers face numerous challenges in their work:

Common Hurdles in Electronics Part Design

Designing electronic components presents challenges such as miniaturization, thermal management, and material selection. Engineers must navigate these obstacles to create successful designs.

Overcoming Challenges with GD&T and Testing Knowledge

GD&T and testing knowledge serve as powerful tools for overcoming design challenges. Engineers who possess these skills are better equipped to address complex issues and find innovative solutions.

Staying Updated with Advancements in the Field

The field of electronics is constantly evolving. Product engineers must stay current with the latest technological advancements and design methodologies to remain competitive.

8. Training and Skill Development for Product Engineers

Formal Education vs. On-the-Job Training

Product engineers can acquire skills through formal education, such as engineering degrees, or through on-the-job training and mentorship programs. Both paths have their advantages.

Professional Development Resources

Continual learning is essential in engineering. Product engineers have access to a wealth of professional development resources, including workshops, conferences, and online courses.

Building a Skill Set for Success

Product engineers should actively build a skill set that includes technical knowledge, problem-solving abilities, GD&T expertise, and testing knowledge to excel in their roles.

9. Real-world applications and Success Stories

Industry Examples of Engineers Leveraging GD&T and Testing Knowledge

Several industries have seen remarkable success by integrating GD&T and testing knowledge into their product engineering processes. These examples showcase the potential benefits.

Achieving Superior Product Quality and Innovation

By combining GD&T and testing knowledge, engineers can achieve superior product quality and drive innovation in the electronics industry.

Lessons Learned from Success Stories

Examining the lessons learned from successful product engineering endeavors can provide valuable insights for aspiring engineers.

Conclusion

In conclusion, product engineers are the backbone of the electronics industry, tasked with designing and optimizing components to meet stringent quality standards. To excel in this role, engineers must possess a diverse skill set that includes technical proficiency, problem-solving abilities, and expertise in tools like GD&T and testing knowledge. By leveraging these skills, product engineers can ensure the creation of optimal electronic parts, contributing to the advancement of technology and the satisfaction of end-users.

-

Instagram4 years ago

Instagram4 years agoBuy IG likes and buy organic Instagram followers: where to buy them and how?

-

Instagram4 years ago

Instagram4 years ago100% Genuine Instagram Followers & Likes with Guaranteed Tool

-

Business5 years ago

Business5 years ago7 Must Have Digital Marketing Tools For Your Small Businesses

-

Instagram4 years ago

Instagram4 years agoInstagram Followers And Likes – Online Social Media Platform